Services & Products

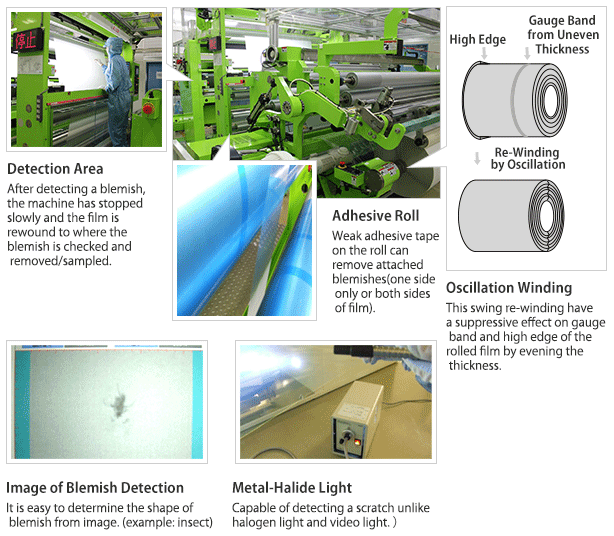

We detect minute blemish, scratches, dirt and dust on the surface of the material in the cleanroom.

Applications | Processing Methods |

|---|---|

| Inspecting・Removing

|

We detect minute blemish, scratches, dirt and dust on the surface of the material in the cleanroom. We also output images and remove unwanted substances accurately.

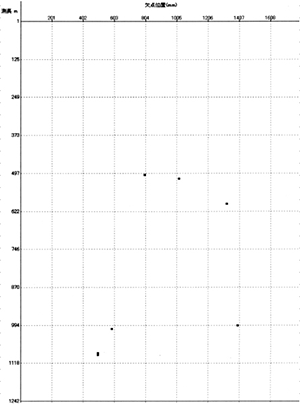

The inspection results are available with a printed map.

Inspection Methods

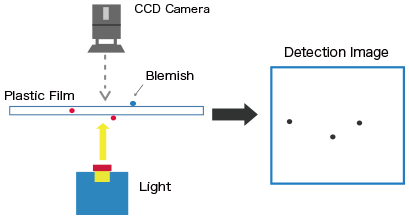

Transmission Method

Inspected blemish appears as black points by transmitted light.

- For Transparency and Translucent Films

- Detectable Colored Blemish, Fish Eye, Pinhole(only for translucent films), Band(appear as a shade), and Tarnished blot.

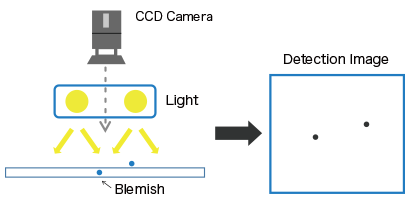

Diffuse Reflection Method

Inspected blemish emerge as light and shade by diffuse reflection.

- For Light-Blocking Films

- Detectable Colored Blemish, Fish Eye, Pinhole(only for translucent films), Band(appear as a shade), and Deep Tarnished Blot.

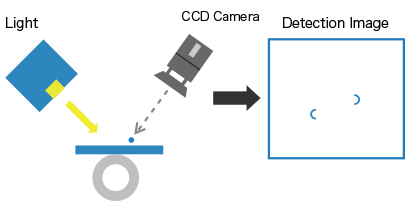

Specular Reflection Method

Inspected concavity and convexity blemish are displayed as shade by shedding light from the side.

- For Light-Blocking Films

- Detectable Concavity and Convexity of surface, Colored Blemish, and Band(appear as a shade).

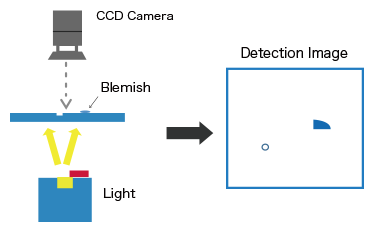

Two-Stage Slit Method

Inspected uneven coating and scracth appears by disturbing light.

- For Transparency and Translucent Films

- Detectable Uneven Coating and Scratch.

Processable Films

Size

Thickness(µm) | Width(mm) | The Maximum Diameter of Roll (mm) | |

|---|---|---|---|

Size of Materials | 12~350 | 200~1,750 | 1,000 |

Materials

PET TAC PC PI PEN OPP

Inspection Resolution

TD(mm) | MD(mm) |

|---|---|

0.039 | 0.025 |

Cleanliness

0.5μm actual value 1,000 ~ 6,000/cf

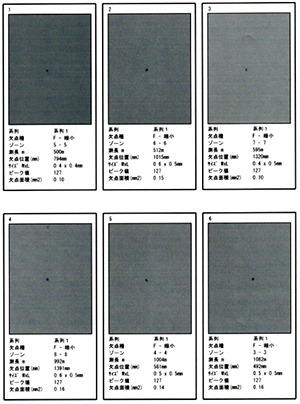

Examples of the inspection data

Placement map of errors

Images of errors

For Sample :Image of Blemish Detection

- Kaisei Industries, Inc. specializes in processing of sandblasting, brushing, slitting, inspection, water cleaning and others for plastic films.

-

We are proud of our surface treatment technologies of sandblasting/sand matting and brushing/hairline with our own mechanical design. Films, which are processed with those technologies, are used in a wide range of industries such as industrial labels, processing base materials, and decorative films for electronic devices, automobile, home electrical appliance, building material, and packing.

To meet the high quality demand of products like slitting and Inspection, processing in a clean room have brought high reliability from our customer for many years.