Services & Products

Matte Coating・Kneaded Matte・Embossed Matte・Non-Fller Anti Glare

Applications | Functions | Processing Methods |

|---|---|---|

|

|

|

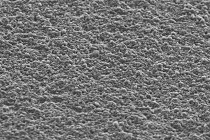

Matte Coating

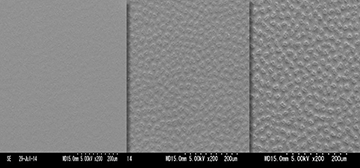

Filler is applied to the surface of films by ultraviolet coating.

Thickness(μm) | Surface Gloss Ratio(%) | Surface Roughness(μm) | Width(mm) |

|---|---|---|---|

12~250 | 2.7~ | 0.3~ | 600~2250 |

※The values in the table are measured data and are not guaranteed.

- Applications:Matte Transfer, Optical Films

- Support :Customized coatings are available upon your request.

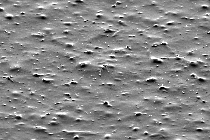

Kneaded Matte

Filler is kneaded into films.

Brand | Thickness(μm) | Surface Gloss Ratio(%) | Surface Roughness(μm) |

|---|---|---|---|

A | 50 | 20±5 | 0.47 |

B | 26 | 30±5 | 0.26 |

C | 25、50 | 40±5 | 0.22 |

※The values in the table are measured data and are not guaranteed.

- Applications:Taking the air out during production process, Colored Films, Matte Transfer, Antiblocking

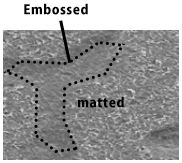

Embossed Matte

Embossed/pressed films by metal roll on the sandblasted surface.

Brand | Thickness(μm) | Surface Gloss Ratio(%) | Surface Roughness(μm) |

|---|---|---|---|

A. Sandblasted + Embossed | ~75 | 10〜 | 1.23 |

B. Small Embossed | ~75 | 50〜 | 1.59 |

C. Large Embossed | ~75 | 20〜 | 3.57 |

※The values in the table are measured data and are not guaranteed.

- Applications:For deeper and rougher surface than sandblasted films

- Support :Various designs of embossed films are also available.

Non-Filler Anti Glare Film (NFAG)

Features

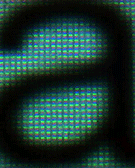

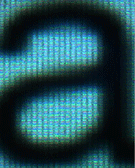

- 1.Light scattering only on asperity of surface coating films enables the brighter and more clarity screen than general filler anti glare types.

- 2.It is suitable for pen/graphics tablets because a moderate friction provides a smooth drawing effect like sketching on a paper.

- 3.The AG surface is not scratched or damaged by continuous sliding with a stylus pen.

- 4.This film is also appropriate for the use of smartphone’s after-sales products such as protective films because the newton ring won’t occurred on the roughened surface.

Regulating size, height and density of island from the sea-island structure change haze and glare. |

Filler type |

NFAG |

Brand | Pencil Hardness | Scratch Resistance | Total Light Transmittance(%) | Haze(%) | Surface Gloss Ratio(%) |

|---|---|---|---|---|---|

A | H~H2 | ○ | 88.3 | 18.0 | 36.0 |

B | H~H2 | ○ | 88.9 | 9.5 | 45.6 |

C | 2~3H | ◎ | 87.9 | 8.5 | 45.4 |

D | 2~3H | ◎ | 89.4 | 4.6 | 61.0 |

E | 2~3H | ◎ | 91.1 | 2.4 | 94.3 |

※The values in the table are measured data and are not guaranteed.

Test Procedure

| Pencil Hardness | JISK5600 750g loaded |

| Scratch Resistance | Steel Wool#0000 200g loaded10rounds ◎=no scrach/ ○=No practical issue |

| Total Light Transmittance・Haze | JISK7105 Incident light into hard coat side |

| Surface Gloss Ratio | JISZ8741 60° on both incident light and reception. |

- Kaisei Industries, Inc. specializes in processing of sandblasting, brushing, slitting, inspection, water cleaning and others for plastic films.

-

We are proud of our surface treatment technologies of sandblasting/sand matting and brushing/hairline with our own mechanical design. Films, which are processed with those technologies, are used in a wide range of industries such as industrial labels, processing base materials, and decorative films for electronic devices, automobile, home electrical appliance, building material, and packing.

To meet the high quality demand of products like slitting and Inspection, processing in a clean room have brought high reliability from our customer for many years.